The Grease Traps Separator,

The automatic grease traps separator is designed to protect the environment from sewage water pollution. It is a device that connects between washing machines, wash basins and sewage.

• Automatically removes grease and oil from waste water.

• It avoids blocking sewer pipes and protects the sewage pumping system.

Application

The separator is constructed and designed to be used in gastronomy. Shackle to connect to kitchen appliances and restaurants where food is prepared in order to avoid being thrown into sewers and environmental contaminants as they are; fat, grease and oil residues and other residues that remain during cleaning of food containers.

Ideal for connection to:

➢ Work cooking stations

➢ Dish washers

➢ Sinks

➢ Rotisseries

➢ Combi ovens

The Advantages

This machine, operated automatically, separates oil from other wastes which can eventually be thrown into the sewer system. In its entirety, our product is aimed to protect the environment by eliminating oil and other debris from entering the sewerage system.

The power consumption is minimal as it uses 12v voltage currents. This is a novelty that is applied to this equipment due to the low humidity of electric power also in the first place for the safety (100% guaranteed) of employees working in the environment where the equipment is installed.

The mechanism for the separation of fats and oils is also familiar with the essence of its mission since it is a much more advanced mechanism than other similar equipment that is present in the market. Due to the reshaping of the oil separator mechanism, this equipment can make up to 96% water purification.

The speed and volume capacity of water separation is twice as high as that of similar equipment. This achievement is thanks to the advanced and sophisticated innovation that has been applied. The separation mechanism, which is the essence of the resuscitation, except that it is very advanced also affects the dimensions of the equipment.

As this machine splits the fat and oil rapidly, the equipment of this device does not necessarily need to be large in size. Due to this fact, this product makes it even more marketable as the dimensions can be constructed in a premise smaller in space, and thus space savvy.

The Department for Solid Waste Disposal and the Division for Fats and Oils.

The oil that is separated from this equipment can then be used as fuel for vehicles and various other purposes.

Protects sewer from sealing and grease pollution.

The next innovation in this device is the pipes that are constructed to be fitting – demountable to make the equipment easier to transport.

All materials from which the appliance is made are resistant to corrosion and temperature.

How it Works

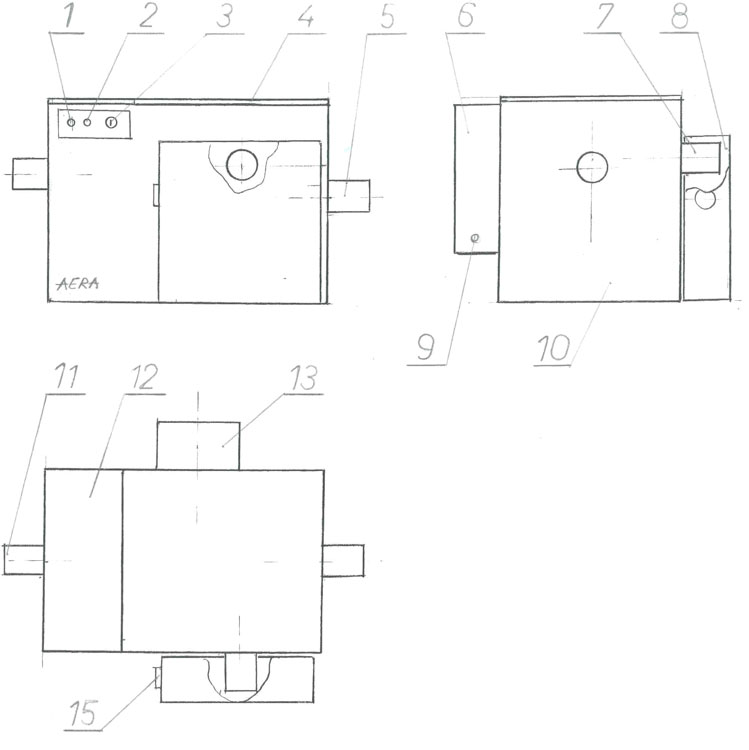

The grease and oil grease are fed into the equipment through the inlet hose (fig.11). The appliance is filled with water until the level of the outlet pipe (fig.nr.5.). In the entrance there is a large size filter that serves for the collection of solid waste of food such as garlic and garbage. The function of this filter is that through the separation of the solid substances it is possible for the equipment to move only fluid fluids such as oils and water fats. Fats and oils are removed from the middle of the oil and fat cleansing unit (fig.no.13) and are automatically disposed out the pipe (fig.7) in the fat-resistant vitreous conduit (fig.8) which when oil is filled during work, removes the equipment and drains through the hole (fig.15). In this way, only clean water without fat and granulate contaminants will flow in the drain pipe (fig.nr.5) connected to the sewer pipe.

Commercial / industrial kitchens

Each commercial kitchen has three main areas of its most effective functioning:

Commercial kitchens are extremely busy environments where they aim to provide quality services to their customers. One of the major challenges the commercial kitchens are facing is the third area which is very difficult to maintain, it can cause insecurity to provide a qualitative food because of problems with drainage systems, grease and debris.

What causes blockage of tubes in commercial / industrial kitchens?

Fats and oils used in the preparation of food in industrial kitchens are the main causes for sealing of sewerage pipes in commercial kitchens. In industrial kitchens, food preparation and cleaning are the main activities where washing equipment and grease maintenance are the main bottlenecks of industrial kitchens. Spilled water may contain fat which is the main cause of blockage of the tubes and cannot be released into the sewage system. In combination, these factors can affect the safety of food, health, and the environment. If these are not efficiently managed, they can block pipes (regardless of size).

Signs indicating that commercial / industrial kitchens should be cleaned

Tubular fat collection is a special challenge for restaurants that use a lot of fat during the cooking process where their restaurants are served many times throughout the day. In addition to the frequency of keeping their pipes clean, the likelihood of fat loss is commonplace. If you have noticed a slow drain during your use of the sink it may be a sign that there is a waste reservoir in the sewer pipes.

Advantages

Cost management is one of the key factors in business today. Commercial kitchen equipment should include fat and drainage systems which meet its low operating cost function.

The key features of the product are:

- Reducing the risk of food contamination;

- Control of expenditures;

- The speed and volume capacity of water separation is twice as high as that of similar equipment;

- All materials from which the appliance is made are resistant to corrosion and temperatures;

- Equipment reaches up to 96% water purification;

- The fat that is separated from this equipment can be reused